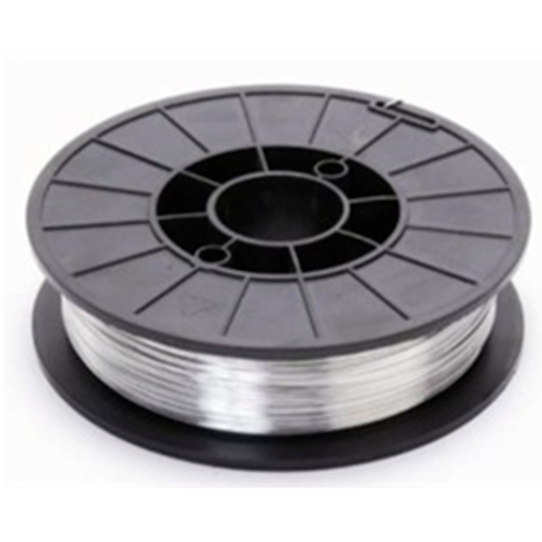

Flux-Cored Welding Wires

Flux-cored welding wire is a new welding material. So it has great adaptability to the base metal, and with high production efficiency of welding. And it widely be used in automatic welding, semi-automatic welding, gas-shielded welding and so on.

The shielding gas, where used, protects the weld pool from oxidation and is usually provided externally from a high-pressure gas cylinder. Weld metal is also shielded by the slag formation from flux melting. Thus the process informally known as ‘dual shield’ welding and was primarily developed for the welding of structural steels. The most commonly used shielding gases are carbon dioxide or blends of argon and carbon dioxide. The most frequently used blend is 75% argon and 25% carbon dioxide. This dual shield method is preferred for welding thicker materials or for out of position welding. This process, when used in identical settings, delivers welds with more consistent mechanical properties and with fewer defects than with MMA or MAG processes. The continuously fed tubular electrode also allows for higher production rates than with solid wire or stick electrode. However, the gas shielded method may not be suitable for use in windy conditions as the disturbance to gas shielding could result in reduced weld metal properties.